PRODUCT

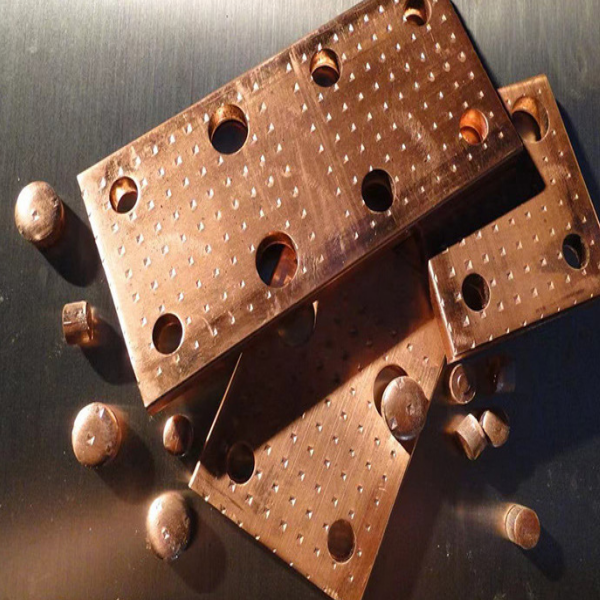

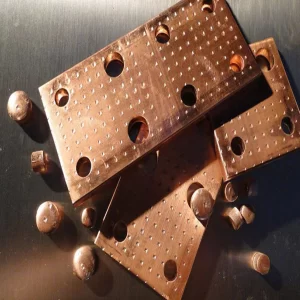

Introduction to CNC copper busbar punching and shearing machine High degree of automation, accurate positioning, high reliability CNC copper busbar punching and shearing machine is a kind of equipment specially used for processing copper and aluminum busbars. It is widely used in high and low voltage complete sets of equipment, switch cabinets, transformer manufacturing, box-type substations, bus ducts and other power and electrical industries. Its main functions include automatic feeding, automatic positioning, automatic clamping, automatic punching, automatic shearing, automatic embossing, as well as automatic mold replacement and automatic material connection, etc. It has the characteristics of high degree of automation, accurate positioning and high reliability. Main functions and features Processing function: CNC copper busbar punching and shearing machine can cut, punch, chamfer, emboss (various round holes, square holes, special-shaped holes and groove shapes) and other processing of copper and aluminum busbars. High efficiency: The equipment has the characteristics of high efficiency, low energy consumption, labor saving and labor saving, and the daily processing capacity can reach more than several tons. High precision: high processing precision, convenient operation, beautiful and novel appearance, the mold frame is made of ductile iron material, good wear resistance, ensuring the concentricity of the upper and lower punching molds during long-term use. Automation: The equipment consists of a feed table, a mold library, a conveying device, a servo control unit and a Lijian busbar processing machine auxiliary design system, etc., with stable and reliable performance and simple human-machine interface operation. Application scenarios CNC copper bar punching and shearing machines are widely used in electrical complete set manufacturing industries such as high and low voltage switchgear, substations, busbars, bridges, electrical switches, communication equipment, household appliances, shipbuilding, office automation equipment, elevator manufacturing, chassis and cabinet manufacturing. It is especially suitable for the production of large-scale electric control boxes and construction sites of power transmission and distribution projects. In summary, CNC copper bar punching and shearing machines play an important role in the power and electrical industry with their high efficiency, precision and high degree of automation.

| Name | unit | parameter | |

| Nominal Force | KN | 500 | |

| X-axis positioning speed | m/min | 30 | |

| Maximum stroke of X-axis | mm | 1200 | |

| Maximum stroke of Y-axis | mm | 950 | |

| Stroke of Pressure cylinder | mm | 80 | |

| quantity of mould | Punching mould | pcs | 4 |

| Cutting mould | pcs | 1 | |

| Embossing mould | pcs | 1 | |

| quantity of control axle | 2 | ||

| accuracy of hole spacing | mm/m | <±0.10 | |

| Maximum diameter of punching | mm | Φ25 | |

| Maximum embossing area | mm2 | 200×60 | |

| Maximum size of the material(LXWXH) | mm | 6000×200×16 | |

| oversize(LXWXH) | mm | 6600×3200×1500 | |

| Maximum hydraulic power | Mpa | 31.5 | |

| total power | KW | 9.5 | |

| Weight | T | 2.2 | |